CTC

CTC is made by vamish coating of cold-processed rectangular copper wire; continuous transposing of 5 to 87 strands of the conductor according th the requirement of the transfomer winding; and coating of insulating paper or other insulating materials. It contributes to the reduction of labor hours because transposing is not necessary during winding of the transfomer; to the reduction of eddy current owing to multiple transposing of conductors; to the reduction of load loss owing to reduced circulation current by the difference of each wire length; and to the enhanced cooling effciency after winding compared to ordinary rectangular copper.

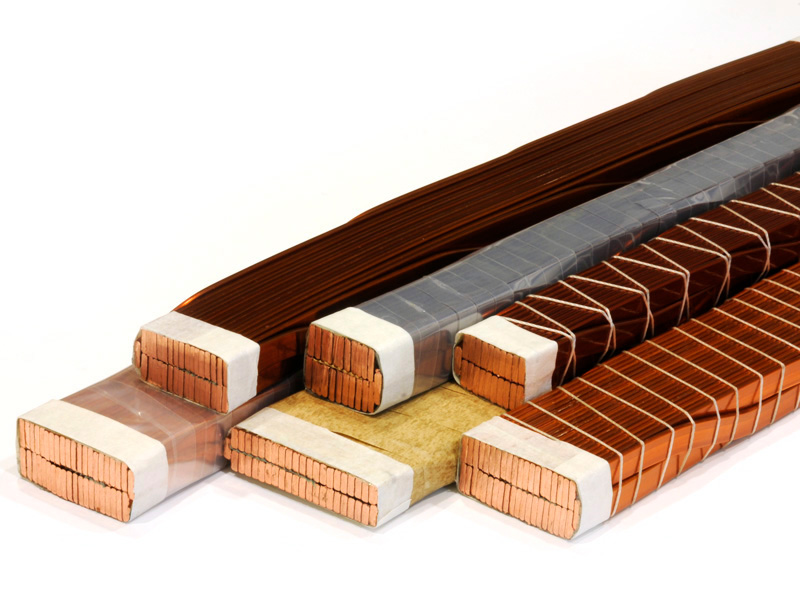

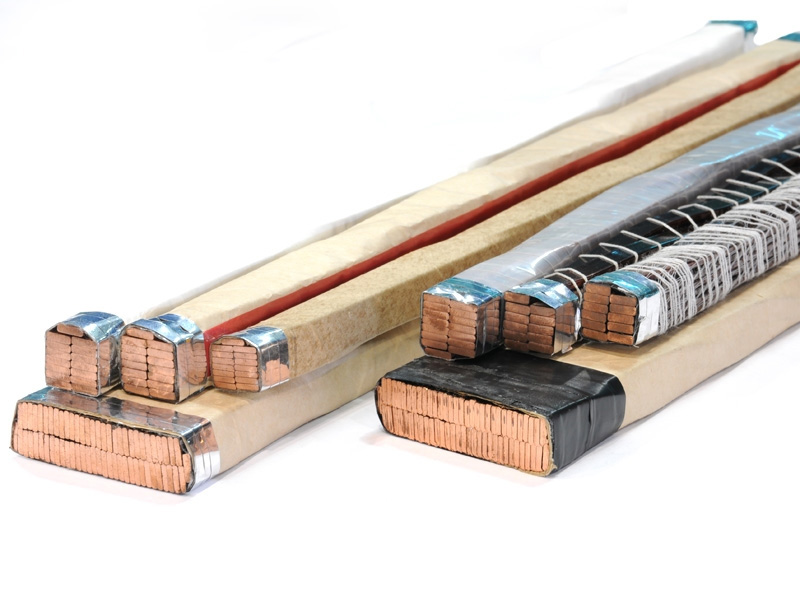

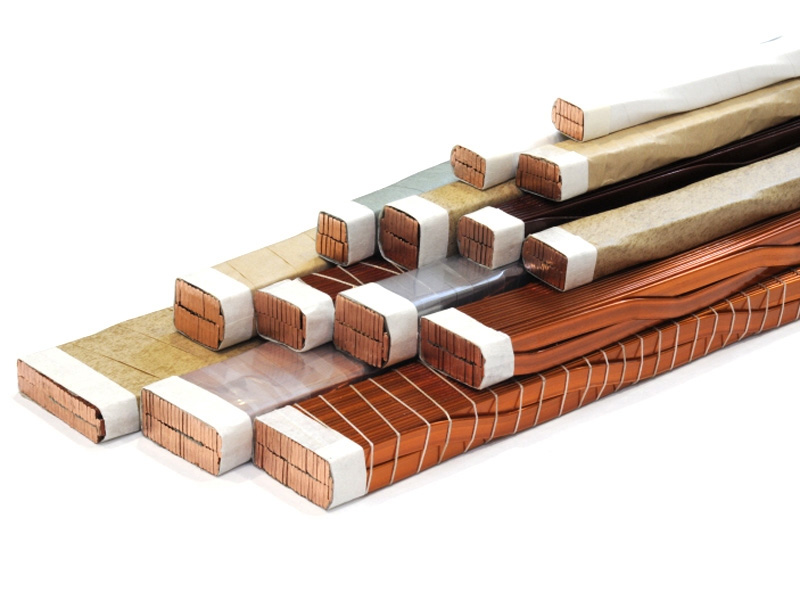

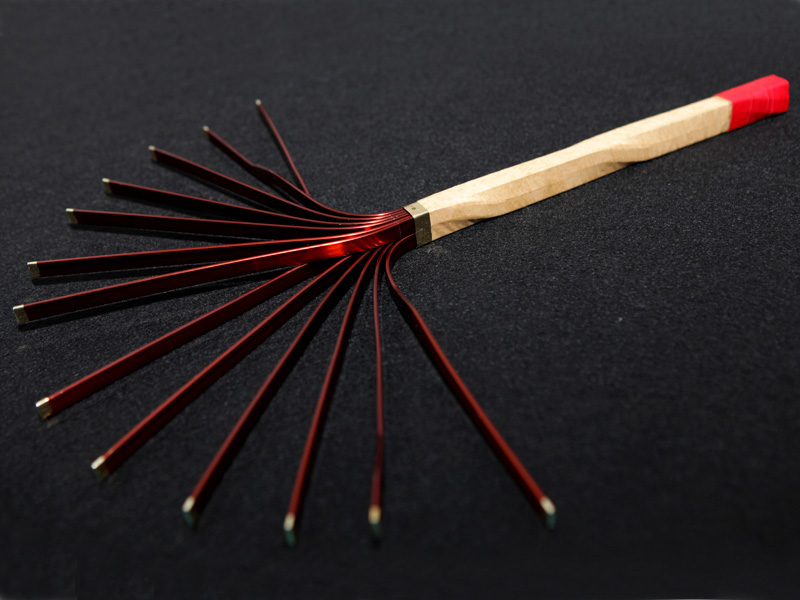

Product Image

Product Info

Use : Windings for low-, medium-, and high-voltage transformers

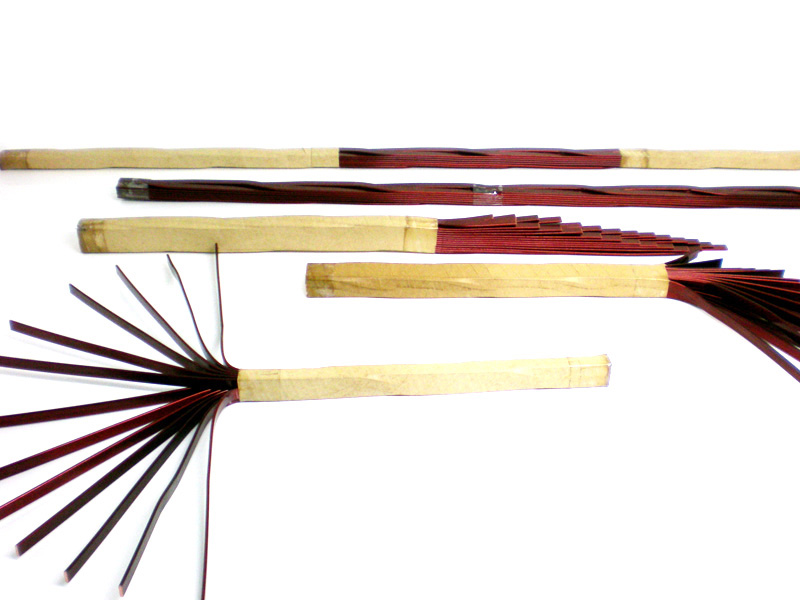

Type : Each strand is transposed sequentially without twisting followed by covering with a layer of insulating paper.

Features : -Reduced working hours during transformer windings by using transposed wire

Reduced loss of transformer owing to reduced eddy current loss by multiple transposing of conductors

Enhanced winding space factor owing to reduced entire cross-sectional area of the winding

(improved cooling efficiency & reduced size)

Increased mechanical strength of the winding through primary enamel coating and secondary self-bond coating of the conductor.

Spec: Number of strands: 5~87

conductor thickness : 1.1mm ∼ 3.2mm

Conductor width : 3.2mm ∼ 12.5mm (ratio of thickness over width=2~6.6)

Remark : CTC is applied to medium to low-voltage as well as EHV transformers; and supplied to domestic as well

as GLOBAL transformer manufacturers.

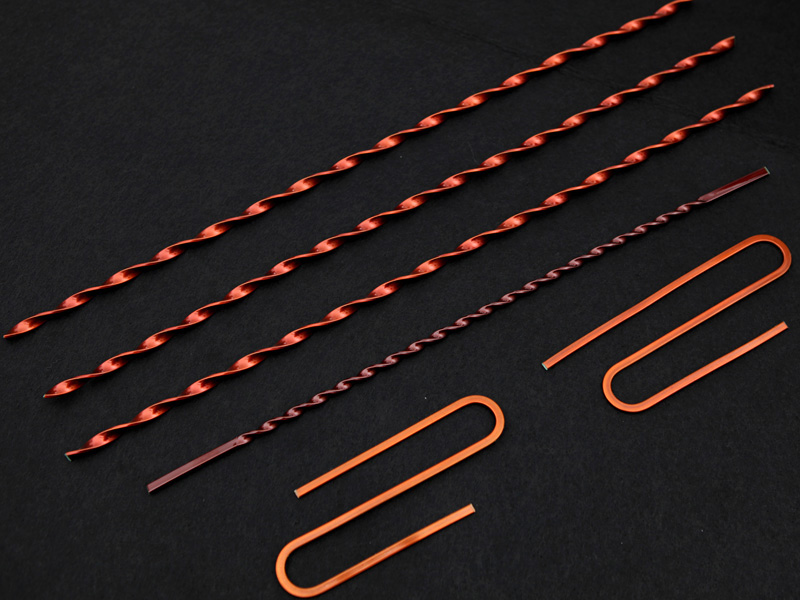

CTC | Production line