Low fin Tube

Home > Low fin Tube

Products

Low fin Tube

This intergral low finned tubes are widely used as heat transfer tubes because of their large external surface area and high heat transfer performance compared with a plain tube.

This enhanced surface fin tubes allow our customers to either reduce the size of the heat exchanger or increase its perfornance.

The low finned tubes we manufacture are designed to meet the most effcient and durable thermal performance for the most challenging situations and long lasting service life.

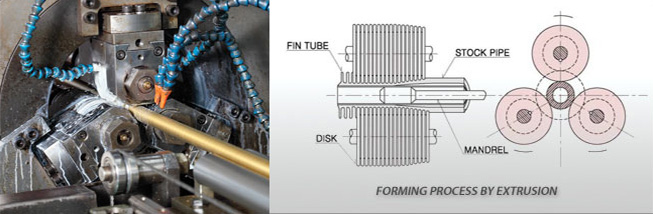

Low Finning Work

The low finned tubes are manufactured in accordance with international standards such as ASTM A498, ASTM A1012, ASTM B359, ASTM B891, ASTM B924 and customer's special requirement.

The low finned tube can be supplied as U-tubes with the bend area finned or plain.

The low finned tube can be supplied as U-tubes with the bend area finned or plain.

Product Range

- • Outside diameter : 12.7 mm(min) ~ 38.1 mm(max)

- • Pitch : 19 ~ 36 FPI

- • Fin height : 0.7mm ~ 1.588mm

- • Length : 20,000mm(Max.)

- • Product capacity per month : 150,000 meter

The Maximum heat transfer ratio of low finned tubes will be up 2.5 to 3 times to compare with plain bare tubes and also it can be not only reduced the cost for new equipment or retrofitting of old equipments but also save the size or weight of new equipment from the beginning stage of basic design.

Cu-Ni(C70600) pipe

Heat treatment facilities

Testing & Inspection procedure

- • Eddy current test

- • Pneumatic test

- • Hydrostatic test as per customer's requirement

Tube bundle assembly work(BP Chemical)

Carbon steellow fin tube, 18,500mm.L.

Low Finned Tube material and application

| No. | Standards | Material | Application |

| 1 | ASTM A498 | Carbon & Carbon alloy | Heat exchanger for Oil refinery and Petrochemical plants |

| 2 | ASTM A1012 | Stainless & Duplex alloy | Condenser and Heat exchanger for Petrochemical & Power plants |

| 3 | ASTM B359 / ASME SB359 | Copper & Copper alloy | Heat exchanger for Petrochemical plants, Condenser & Evaporator for Power plants |

| 4 | ASTM B891 | Titanium & Titanium alloy | Condenser and Heat exchanger for Steam & Nuclear power plants |

| 5 | ASTM B924 | Nickel alloy | Condenser and Heat exchanger for Chemical plants |

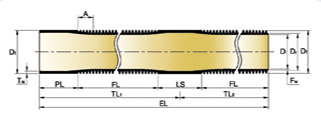

- • Dt : Outside diameter of plain end

- • Df : Diameter over fins

- • Dr : Root deameter of finned section

- • Di : Inside diameter of finned section

- • Tw : Wall thickness of plain section

- • Fw : Root wall thickness of finned section

- • PL : Plain end length

- • FL : Finned section length

- • A : Finned section taper length

- • LS : Land section length

- • TL1, TL2 : Length between plain end and land area

- • El : Entire length

| [ Home ] | [ Send E-Mail ] |